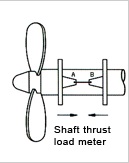

Shaft Thrust Load Meter

What is a shaft thrust load meter?

The shaft thrust load meter measures the shaft compression (longitudinal) strain caused by propeller propulsion.

By measuring together with the torque from the shaft horsepower meter, the propulsion performance can be accurately grasped. If there is a change in the propulsion performance, it is possible to separate and evaluate the cause whether it is due to the increase in hull resistance or due to the decrease of the propeller efficiency. When equipped with a shaft horsepower meter and shaft thrust load meter, the timing of maintenance can be measured, and not only the maintenance cost can be reduced, but also fuel efficiency can be reduced by constantly monitoring the propeller efficiency.

SEC shaft thrust load meter

SEC shaft thrust load meter can detects extremely subtle compression strain of the shaft with an high sensitivity displacement sensor which have a minimum resolution of 0.025 microns.

The shaft thrust load can be measured with high accuracy by correcting shaft torsion based on torque data obtained from the SEC shaft horsepower meter.

As shown in the figure above, the rotating shaft contains both compression strain proportional to the propulsive force and torsion generated proportionally to the torque. In order to measure the true compressive strain (ΔL), it is necessary to know the torsional component “T”. “T” is calculated from the torque data of the shaft horsepower meter. Therefore, a shaft horsepower meter is indispensable for the SEC shaft thrust load meter.

Thrust load display monitor

Monitor capable of displaying a thrust load data will be only the LCD type.

Type of SEC Shaft Thrust Load Meter

SEC shaft thrust load meter has a combine type that measures the torsion and compression strain of the shaft with a single detector ring, a separate type that measures shaft horsepower and shaft thrust load with separate rings, and the same separate type with a temperature compensation type, which is added a function to correct the temperature difference between the shaft surface temperature and the sensor strip temperature.

<Comparison table of measurement accuracy and installation space by type>

| Type | Measurement accuracy | Installation space |

| Combine type | +0.5%, -2.5% or less | 500~600mm(Including service space) |

| Separate type | +0.5%, -1.5% or less |

1,100~1,200mm (incl. the width of the detector ring of Shaft horsepower meter and service space) |

| temperature collection-type | +0.5%, -0.5% or less |

1,100~1,200mm (incl. the width of the detector ring of Shaft horsepower meter and service space) |