Engine Combustion Pressure Monitor

Combustion Pressure Sensor

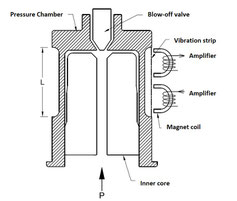

The pressure receiving part of the SEC combustion pressure sensor is not a diaphragm structure, but a pipe structure that is closed at the the top. A thin metal strip is attached a a certain tension to the external surface of the pipe. The tension of the metal strip changes in accordance with pipe length (L), which changes under pressure. The metal strip vibrates under the excitement generated by the coil unit and the amplifier connected to the cable. Its vibration frequency is the natural frequency determined by the tension on the metal strip. As the length of the pipe (L) increase under pressure (P), the tension on the metal strip increases, thus causing the natural frequency to increase. Because there is a proportional relationship between the applied pressure and the natural frequency of the

strip, it is possible to determined the pressure by measuring

changes in the frequency of the strip's vibration.

Feature of the combustion pressure sensor

| ◆ The Electrical component configuration used for the pressure sensor is minimized to increase reliability. | |

|

◆ The coil unit is mounted on a housing with cooling fins. The housing is fixed to the outer cylinder via a heat insulating material. This suppresses the temperature rise of the housing body and operates stably. |

|

| ◆ Super stainless steel is used for the pressure-receiving cylinder and inner core to improve durability. | |

|

◆ By opening the valve on the top of the cylinder, it is possible to blow off the internal deposits, and it can be used semi-permanently by regular maintenance. |